Innovative UV LED Technology

A Sustainable Solution

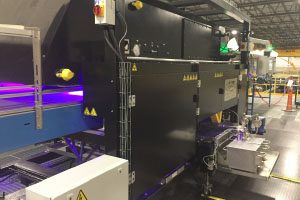

The Roeslein & Associates Ultraviolet Bottom Coating System has been improved with a UV LED curing and control system upgrade.

As an alternative to microwave and arc lamp technology, UV LED technology leads to increased reliability/efficiency, lower power consumption, and an increased 70,000+ hour lamp life.

As an added benefit, the UV LED technology will not interfere with wireless networks, allowing machines and systems in close proximity to operate without interruption.

Reliable

- Increased Uptime & Speed

- Simplified Operation

- Fewer/Longer-Lasting Parts

- Instant On = No Warm-Up Time

- Very Stable Power System

Sustainable

- Improved Safety

- Energy & Noise Conservation

- No Ozone Production

- Reduced Defects

- Fewer Failed Parts in the Waste Stream

Proven

- Over 7.7 Billion Cans Produced

- Over 40,000 In-Production Hours

- Lower Total Cost of Ownership

- Slide-In Retrofit = Quick Install

- ROI Tool – Avg. < 1 Year Payback

Typically, D&I can manufacturers install the UV Bottom Coating System immediately after the washer. One of the key differences between Thermal-cured and UV cured bottom coating materials is a thicker, more uniform coverage.

- Superior control of film weight

- Provides uniform coverage resulting in 10-15% material savings

- Improved adhesion, greater mobility and excellent corrosion resistance the UV cured application offers dry film thickness of 7-9 microns with 100% solids, compared to 1-2 microns with 35% solids with thermal cured application